Stainless-steel General Data En Requirements For Stainless-steel H R Plate

Sheet metal is manufactured and delivered from the processing mill rolled to the standard thickness that you simply specify, which is now metric. The sheet metallic does nonetheless have a tolerance on the rolling thickness which must be taken into consideration when designing a decent fitting meeting, especially because the sheet metal material will get thicker. For example, a metal fabricator supplying components for construction would possibly incur important losses if exact measurements usually are not adhered to.

The Method To Enforce Precision In Your Steel Sheet Selection?

To read a thickness gauge correctly, I start with making certain the gadget is correctly calibrated per the guidelines. Calibration means setting the gauge to an assignable normal in order to get rid of measurement errors. I explain that after calibration I always wipe the floor of the thing being measured in order to take away any contaminants that may affect accuracy. In https://telegra.ph/Everything-You-Need-to-Know-Before-Designing-an-Aquatic-Therapy-Pool-Room-09-08 of digital calipers, I conduct the measurement by masking the jaws of the caliper round an object being measured while maintaining just sufficient pressure with out making the reading unrealistic. I then focus my eyes on the digital screen to take the measurement resolution as much as zero.01 mm.

Us Authorities Necessities For Metal Mill And Foundry Merchandise

Via numerous discussions with engineers and quality control specialists, I've realized that understanding these grade-specific concerns is essential for both producers and end-users. Let me share some insights from our manufacturing experience and buyer applications. For example, when supplying pipes to David's facility for his or her pressure vessel manufacturing line, adherence to these standards was important for maintaining their ISO certification.

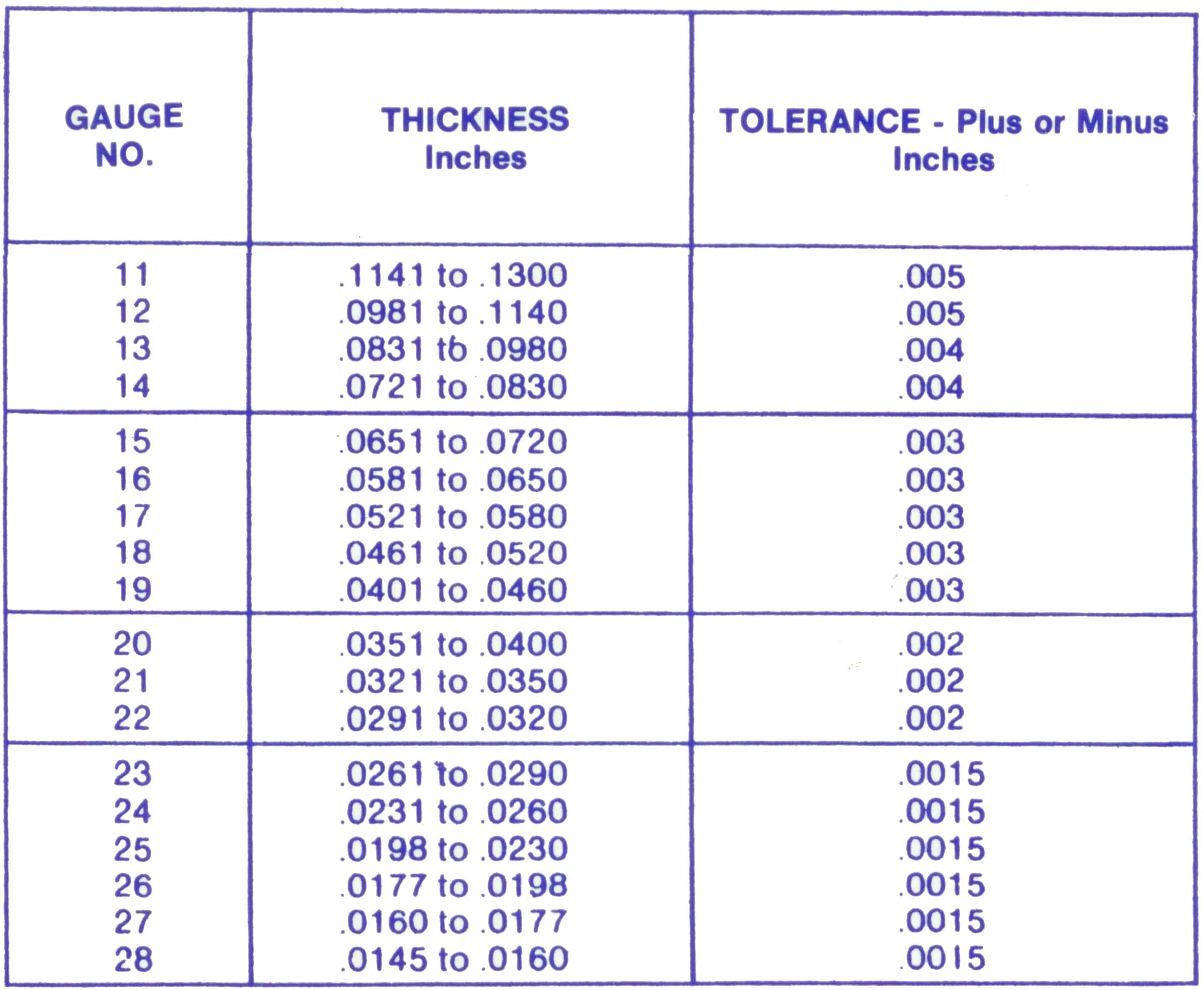

This Is A Vital Time Period, And Tolerances Are Usually Accepted Length Or Thickness Deviations

In Europe, chrome steel plates are ruled by EN standards, which provide particular tolerance lessons. For instance, Class B tolerances apply to ferritic and martensitic grades, while austenitic grades with or with out molybdenum could have totally different tolerance levels. modern adjustable depth swimming pools make sure that materials meet the required specs for varied industrial applications. Correct thickness measurement is important to make sure chrome steel plates meet specified tolerances and high quality requirements, sustaining their structural integrity and efficiency in numerous functions. This is essential for their use in development, automotive, and industrial equipment.

Duplex Pipe Vs 316l: Cease Cl⁻ Stress Cracking

- By following standardized guidelines and guaranteeing precise measurements, manufacturers can produce high-quality, reliable merchandise that meet the stringent demands of contemporary engineering and manufacturing.

- Accuracy in sheet metallic fabrication is essential, but achieving tight tolerances could be a actually difficult task.

- Good design is important for reaching higher tolerances in sheet metallic fabrication.

- As Quickly As the die is finalized, it delivers extremely high dimensional consistency in mass production.

- This degree of flatness is important for purposes where even minor deviations can have an effect on efficiency and sturdiness.

- Gavin Yi is a distinguished chief in precision manufacturing and CNC know-how.

Whereas commonplace tolerances work for basic purposes, specialized industries usually require custom specs. For occasion, I lately helped an Indian pharmaceutical manufacturer supply pipes with extra-tight tolerances of ±0.2mm for their ultra-pure water system. This level of precision was important for maintaining product high quality and regulatory compliance. Flat sheets of metal are converted within the bending course of into exact angles and shapes to be used in varied functions. Press brakes work by clamping supplies between a punch and die and making use of force to create bends.

Cad-linked Parametric Rfq For Metal Fabrication — Prompt, Auditable Quotes From Cad

Tolerance ranges are established to account for the natural variation in the manufacturing course of and be positive that the ultimate product stays within the acceptable range of thickness. The proper Ra worth ensures proper corrosion resistance, simpler cleansing, better weldability, and compliance with trade requirements. Choosing the wrong end, however, can lead to greater maintenance prices, hygiene points, or disappointing aesthetics. Sheet steel bending includes forming metal round a straight axis to create V, U, or channel shapes.

Tolerance Tables For Form And Place Iaw Din Iso 2768-2

Using advanced equipment like a CNC Press Brake can help achieve tighter tolerances more efficiently, bridging the hole between quality and cost. If the half dimension variation vary is not appropriate, corresponding to if the tight tolerances, then a extra precise manufacturing process is required to make sure the accuracy of the completed product. By integrating these practices, manufacturers can achieve correct thickness measurements, guaranteeing their merchandise meet high quality requirements and specifications. By controlling thickness tolerance, you can cut back the amount of scrap materials generated throughout production. Putting this cross-functional stability is a core talent for prime engineers and manufacturing managers alike. Laser scanners offer high precision and are used in industrial applications the place accuracy is paramount. These instruments measure thickness by scanning the floor and providing detailed profiles of the material. Contact Vinmay at present for skilled support, technical steerage, and high-quality stainless-steel options tailored to your requirements. Rougher surfaces can complicate welding, assembly, or sealing, typically leading to longer fabrication occasions and better labor costs. In contrast, CPP Plates are coiled during production, which might introduce residual stresses but presents advantages in dealing with and transport, making them appropriate for lighter, more versatile applications. By following ASTM A480, manufacturers can guarantee their products meet established high quality standards, reducing the chance of defects. Assembly or exceeding buyer expectations when it comes to thickness tolerance can improve buyer satisfaction. Clients are more doubtless to do business with a provider who can present excessive - high quality merchandise consistently. Choosing a reliable and reputable chrome steel provider is crucial to ensure quality, availability, and customer service. Having defined tolerances allows manufacturers to optimize processes, reduce costs, and improve quality assurance measures via standardized high quality management documentation. Tolerances are a crucial facet of steel specification that can considerably affect the efficiency and functionality of finished components. Understanding how totally different tolerance sorts work and their impact on engineering and manufacturing processes is crucial for both engineers and plant managers. This guide aims to illuminate the varied tolerance definitions, illustrate their significance in production, and provide sensible communication tips to improve collaboration between consumers and engineers. Every of these parts is meticulously formed to meet strict tolerance and efficiency requirements. That is how we flip flat sheets of metallic into durable components that fit seamlessly into particular industrial functions. In this weblog article, we present the strongest, hardest and most durable surface therapies. In addition to common tolerances, you presumably can limit the tolerances of shafts and shanks further in the choice tables right here. As a Japanese manufacturer, MISUMI manufactures its products according to JIS B0401, which is equivalent to ISO 22081. Shear angle tolerance is ± 1.5°;When the bending angle just isn't 90°, the angle tolerance is ± 1.5°;When the bending angle is different angles, the angle tolerance is ± 3.0°. For sanitary functions, Ra ≤ zero.8 µm (mirror-polished or 2B finish) is ideal, decreasing bacterial buildup and making cleaning simpler. For widths above 30mm it is measured at any point no less than 10mm or 15mm from the longitudinal edges for slit or mill edges, respectively. As in EN there are two methods to specify out of squareness and the values are identical to this normal. This does not apply to materials in the work hardened condition which must be agreed on the time of the enquiry and order. The phrase “specified thickness” is most well-liked to “nominal thickness” on this ISO commonplace.

Case Examine: Structural Bracket

Plates with massive deviations might warp or bow, impacting their flatness and general floor end. Standards like ASTM A480 provide detailed specs for thickness and flatness tolerances. These standards ensure consistency across different suppliers and purposes, facilitating world commerce and manufacturing processes.

Quality Control And Sheet Steel Tolerances Management

Tolerances in design are usually defined because the deviation of a dimension from its perfect worth. This deviation is split into tolerance courses that decide the effects of the deviation. In EN 10029, the inscribed rectangle definition was not restricted to plates with untrimmed edges. There are 3 courses of tolerance for width and length for plates with trimmed edges A – C. Quality management is essential for maintaining precise tolerances and guaranteeing product reliability. These guidelines and requirements assure quality and consistency across completely different producers and industries. Studying these variations is important for choosing the suitable process for your project needs. The acceptable range of deviation from measurements or explicit dimensions for a manufactured element or half is called Manufacturing tolerance range.